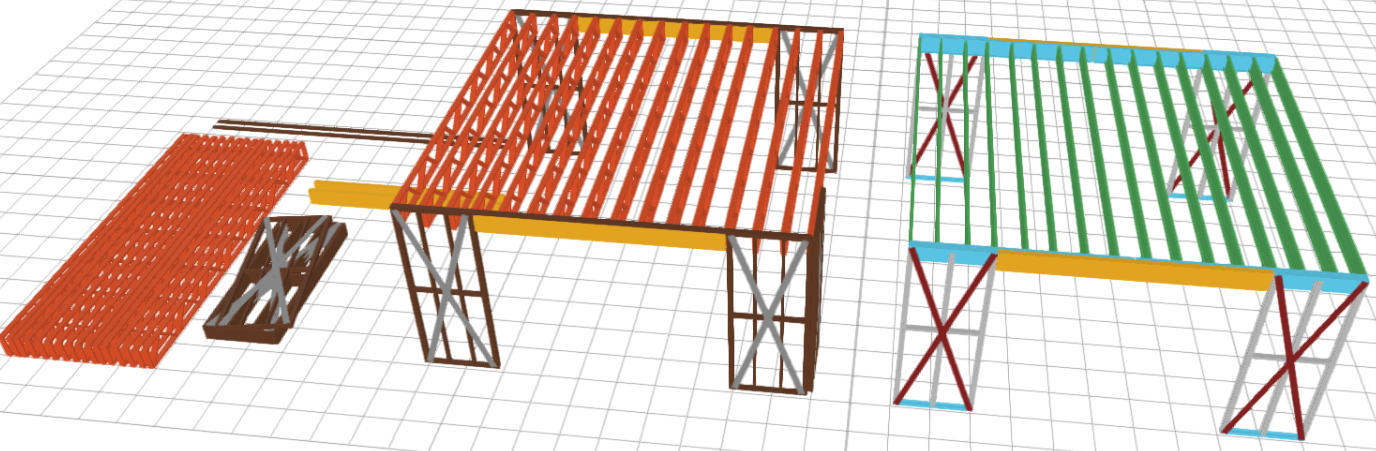

Light-Gauge Steel framing or Wood, which is the right one for my home? LGS on the right, Wood on the left.

The Ironwood Home was originally designed for metal framing, primarily for fire resistance, strength and easily prefabricated wall, floor and roof sections. The framing consists of 16-gauge galvanized members for all structural components with 20-gauge framing at non structural walls. Where non-structural walls occur at the exterior, 20-gauge galvanized studs are used.

The beams can be a built-up box beam or a tube steel beam. The floor trusses are engineered or off-the-shelf products. The 20′ x 20′ structural frame dimension was chosen largely due to the limitations of a floor joist at 12″ deep by 20′ long. Increasing this span would have required deeper floor joists. Studs can be 16″ or 24″ on-center when using metal framing. I design with 24″ OC as the standard. Wall stud framing is kept to the same dimensions as lumber to make installing everything else in residential construction easier. 3-1/2″ studs vs. 3-5/8″ used in commercial applications.

Wood elements are used with the metal framing to create thermal breaks and to allow for the installation of standard residential windows and doors. Wood is not used for structural components. The exception is plywood sheeting which is used for horizontal and vertical shear surfaces. Wherever wood is used, it is not exposed directly to the exterior. It is always covered by insulation and non-combustible siding and trim.

Wood usage on the interior is fair game. I love the look and feel of wood and recommend its use with interior design. The downside is it adds fuel load to the home in the event an interior fire is ignited. Early fire detection and fire sprinklers are there to help lower these risks.

The consideration of using all wood framing is a recent change for me and still not my first choice. The addition of wood framing is to bring the costs of a new home down even further and since nearly all builders are familiar with wood it seems to be an option I shouldn’t pass up.

Because we can keep the efficiency and high-quality construction that light-gauge steel provides, wood became a viable option. The structural frame is still made up of the same 3 main components and can be prefabricated just like its steel counterpart. Wall panels, floor trusses and roof sections are all prefabricated on or off-site. None of these components requires a factory, large cranes or trucks.

The makeup of the shear panels needs to be explored in greater detail. Primarily the use of double studs and tie-downs at each corner. I am assuming these will perform much the same as with LGS. Wood framing is always set at 16″ on-center.

We can make a fully wood-frame home very fire resistant from exterior sources the big difference is the structural elements will burn if the fire gets in. Wood still presents the other issues any wood-frame home faces such as being more susceptible to rot and insect damage however the Ironwood Design provides construction details which will minimize these risks as well.

In the end it all comes down to quality in construction. The Ironwood Home plans provides and requires construction details intended to greatly increase quality in every home built. A well-built home will be fire-safe, strong, comfortable and quiet whether it is framed from light-gauge steel or wood.

Why Ironwood? | Why Build Ironwood? | Plans & Specifications | Fire Safe & Strong | Energy-Efficient